You can contact us via phone and email or use our contact form.

We are looking forward to hearing from you!

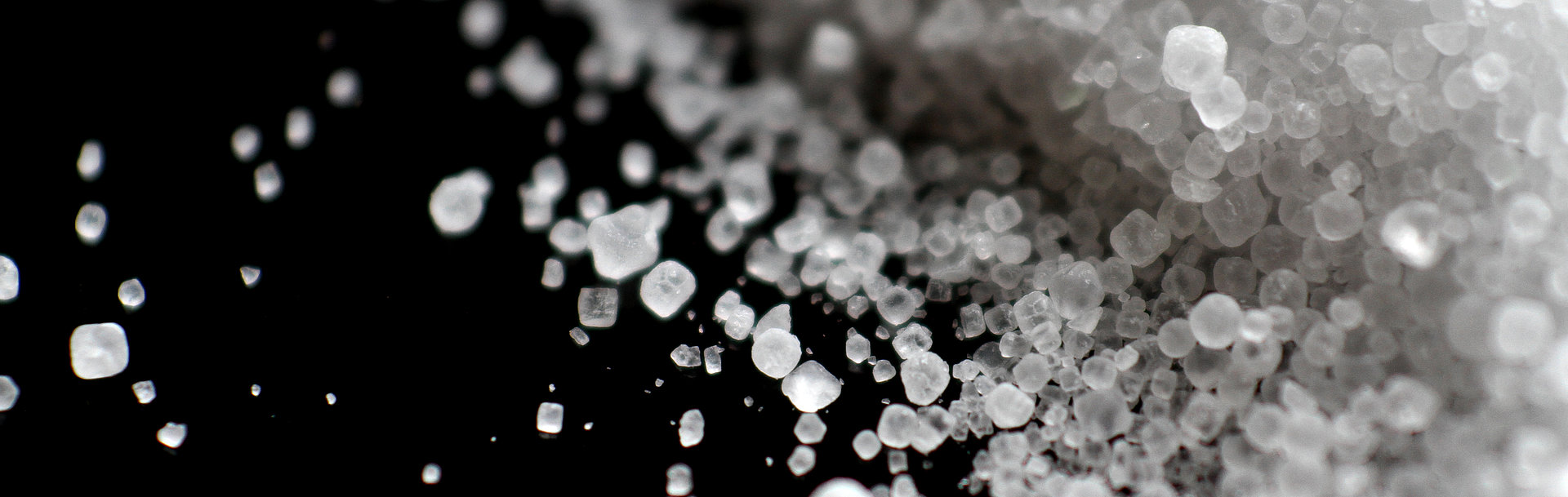

Sugar

Markets

The production and handling of crystal sugar creates dust – for example during drying, at the sieving and packing station or at transfer points in transport. We can apply solutions and equipment at all of these places. Riedel Filtertechnik has been an established partner to the sugar industry for decades. Our profound process expertise makes us more than simply an equipment supplier: We are a solution partner on issues of sugar conditioning and silo dedusting. Together with our customers, we develop individual concepts for their process dedusting and for sugar conditioning. To permanently guarantee the quality of ready-for-sale sugar, sugar conditioning is crucial. We supply our customers’ conditioning and storage silos with air of a regulated quality and ensure it is distributed as well as possible. The result? Consistent sugar quality. In addition: Since sugar dust is explosive, the safety of humans and machines is of utmost importance during its removal. Explosion protection measures are an integral part of systems. In addition, the recovery of sugar from the process exhaust air contributes to increasing the yield. This means our partners from the sugar industry benefit twice in terms of sugar conditioning and silo dedusting.

Your requirements

- Efficient to operate due to minimal energy requirements and low operating costs

- Low manpower thanks to a high degree of automation and simple maintenance

- Maximum reliability through 24/7 availability and ensured process stability

- Worry-free use in terms of explosion protection, contact with food and compliance with emission limits

Our services

- High process expertise for optimal system design

- Individual solutions for precisely your requirements – from individual systems to complex filter systems

- Silo conditioning system for consistent sugar quality

- Integrated structural explosion protection – certified per ATEX guidelines

- Pressure shock resistant and pressure resistant design in standard steel and stainless steel

- Automation tailored to process technology thanks to in-house programming

- Flexible connection to control systems or IIoT requirements

Your project is our focus

CONCEPT PLANNING

Demanding projects require good planning. Our technical sales team will work hand-in-hand with you to develop a solution that perfectly meets your requirements. Find the right contact person for your project.

ENGINEERING & AUTOMATION

We use our technical expertise, the latest 3D applications and cutting-edge programming languages to create your individual project. We offer industry-specific expert knowledge and decades of experience in handling global projects – all from a single source.

PRODUCTION

Production, pre-assembly and quality testing activities take place at our main site in Leopoldshöhe, Germany. We excel in worldwide shipping and export matters to deliver our solutions to your door.

INSTALLATION

Riedel's experienced personnel will ensure trouble-free installation and commissioning of your system at your site – mechanical and electrical assembly combined. We would be happy to accompany you during subsequent official acceptance measurements.

AFTERSALES SERVICE

We are there to help you with any questions you may have and are your long-term partner when it comes to maintenance & repair, optimization & upgrade and spare parts.

Products

- Silo conditioning

We keep your sugar free-flowing - thanks to optimal conditioning and storage conditions. Even when sugar is dried and cooled, residual moisture remains in the crystals. The consequence? Lumps can form. We can minimize this risk - with the help of our silo conditioning system: We condition the sugar to defined process parameters using air of controlled quality. The conditioning air is extracted, dedusted and returned to the process.

- Fabric filters

Our dedusting solutions can achieve clean gas dust contents below 1.0 mg/m³ as standard. Furthermore, in many cases, the air can be fed back into production. The result is that dust emissions are reduced by using fabric filters and we play our part in taking care of our environment. Our JMS hose filters, JMP cartridge filters and JMT bag filters are cleaned automatically with compressed air. These dedusting solutions are also available in stainless steel, with pressure shock resistance, trace heating and insulation as well as fire and explosion protection. We have the expertise to find the right type of industrial fabric filter for your production requirements.

- Venturi & absorption scrubber

Venturi scrubbers are a proven, industry wide solution for air pollution control. Our HNA venturi scrubber can reliably remove dust from damp exhaust air flows. This wet scrubber is designed to clean gas dust content of below 5.0 mg/m³ with reasonable energy expenditure. The scrubbing liquid is treated and cleaned via automatic belt filters or time-controlled outlet valves, which empty automatically during the operation of a partial load. The absorption scrubber reduces acidic and basic as well as gas-laden components in the exhaust air to the permissible values.

- Pneumatic transport

Bulk materials such as cut tobacco, tea, chips or crystal sugar are transported gently with our pneumatic transport system to keep production changes to an absolute minimum. Our patented SACU tobtronic® is the most effective and safest technology to ensure blockage-free, pneumatic conveying of bulk materials at a low speed. The patented FPC pipe couplings avoid gaps and edges that can affect the bulk material.

- VAC & NetVac® – Industrial central vacuum cleaning systems

Our industrial central vacuum cleaning systems improve the working conditions of your employees, increase plant availability and reduce wear and tear. Industrial central vacuum cleaning systems are more efficient than mobile industrial vacuum cleaners. These central vacuum cleaning systems ensure that any removed material, such as dust, bulk material or production residues, are collected in a central location. As a result, waste disposal is much simpler. There is no limit to the number of cleaning points that can be installed.

- Central dust and material handling – industrial dust collection system

A central industrial dust collector enhances the efficiency and cleanliness of machines, systems and buildings. Our dust collector systems consolidate bulk materials, dusts or products at central locations. When the dust collection system is in suction operation, the bulk material is automatically taken from the collection points and then transported over long distances. At the receiving point, the product is sent for further processing, loaded or compacted for disposal.

References