You can contact us via phone and email or use our contact form.

We are looking forward to hearing from you!

Tobacco

Markets

We have been an innovative partner to the tobacco industry for over 50 years. We are established worldwide as a system supplier of exhaust air purification, dust handling solutions and industrial odour reduction systems for cigarette production lines. Our pneumatic transport systems, central vacuum cleaning systems and machine cleaning systems are designed to achieve our main goals: environmental protection, energy efficiency and increased yield in tobacco production. We continue to innovate in the primary and secondary sectors with effective and patented technologies. We reduce energy consumption on the cigarette production line: our products save electrical energy, compressed air and conditioned air. Plus, there is energy recovery from exhaust air flows. We would be happy to advise you on further potential for energy savings in your cigarette production line using our assessments as a basis.

Our systems are designed for continuous operation with low maintenance requirements. It goes without saying that they meet all the requirements of occupational and operational safety in the tobacco industry and environmental protection. Product-specific requirements in cigarette production are met in accordance with local and international standards. The same applies to fire and explosion protection, which, when necessary, we take into account as an integral part of the systems.

Your requirements

- Reliable availability of tobacco manufacturing machinery and systems

- Reliable operation

- Increased tobacco yield

- Low operating costs

- Low energy and spare part requirements

- Low maintenance requirements

- Long service life of cigarette manufacturing machinery and systems

For tobacco processing Primary

- Pneumatic conveying of tobacco and tobacco stems

- Industrial air filtration for dryers, conditioning drums and coolers

- Industrial air filtration for tobacco recovery systems

- Industrial air filtration for mechanical handling systems

- Industrial air filtration for production facilities of alternative products

- Industrial odour control

- Heat recovery

- Industrial central vacuum cleaning

For cigarette production Secondary

- Minimal tobacco degradation

- Recovery and return of tobacco shorts

- Recovery, preparation and return of winnower

- Pneumatic conveying of cut tobacco

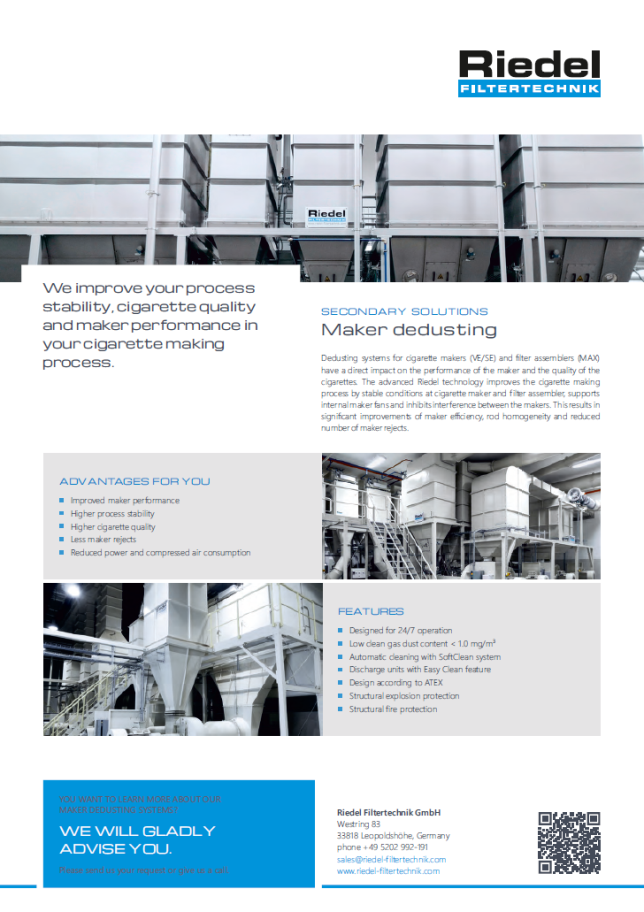

- Industrial air filtration for cigarette makers

- Industrial air filtration for filter making machines and filter assemblers

- Industrial odour control

- Industrial central vacuum cleaning

- Energy and baseline assessment

Dust and material handling

- Central dust collection for industrial air filtration systems

- Central material collection for ripping machines

- Dust and material filling

- Dust and material compaction

Your project is our focus

CONCEPT PLANNING

Demanding projects require good planning. Our technical sales team will work hand-in-hand with you to develop a solution that perfectly meets your requirements. Find the right contact person for your project.

ENGINEERING & AUTOMATION

We use our technical expertise, the latest 3D applications and cutting-edge programming languages to create your individual project. We offer industry-specific expert knowledge and decades of experience in handling global projects – all from a single source.

PRODUCTION

Production, pre-assembly and quality testing activities take place at our main site in Leopoldshöhe, Germany. We excel in worldwide shipping and export matters to deliver our solutions to your door.

INSTALLATION

Riedel's experienced personnel will ensure trouble-free installation and commissioning of your system at your site – mechanical and electrical assembly combined. We would be happy to accompany you during subsequent official acceptance measurements.

AFTERSALES SERVICE

We are there to help you with any questions you may have and are your long-term partner when it comes to maintenance & repair, optimization & upgrade and spare parts.

Products

- RIEDEL GreenLine

With energy costs and environmental concerns on the rise, optimising energy consumption in cigarette production is essential. As a result of our research and development and intensive development cooperation, Riedel developed the GreenLine concept, which is supported by the Maker Airflow Control (MAC), SACU tobtronic®, SoftClean and state-of-the-art Eco Mode automation system and achieves significant energy savings.

- Fabric filters

Our dedusting solutions can achieve clean gas dust contents below 1.0 mg/m³ as standard. Furthermore, in many cases, the air can be fed back into production. The result is that dust emissions are reduced by using fabric filters and we play our part in taking care of our environment. Our JMS hose filters, JMP cartridge filters and JMT bag filters are cleaned automatically with compressed air. These dedusting solutions are also available in stainless steel, with pressure shock resistance, trace heating and insulation as well as fire and explosion protection. We have the expertise to find the right type of industrial fabric filter for your production requirements.

- Venturi & absorption scrubbers

Venturi scrubbers are a proven, industry wide solution for air pollution control. Our HNA venturi scrubber can reliably remove dust from damp exhaust air flows. This wet scrubber is designed to clean gas dust content of below 5.0 mg/m³ with reasonable energy expenditure. The scrubbing liquid is treated and cleaned via automatic belt filters or time-controlled outlet valves, which empty automatically during the operation of a partial load. The absorption scrubber reduces acidic and basic as well as gas-laden components in the exhaust air to the permissible values.

- COPLAS clean – Odour reduction with cold plasma

Our cold plasma treatment eliminates odours just like nature, only faster. COPLAS clean is our non-thermal plasma technology for industrial odour control. Odours are eradicated without any chemicals, water or waste. Our patented plasma reactors produce reactive oxygen and OH radicals, which are then injected into the exhaust air. The ingenious result is that odour molecules are oxidised in just milliseconds by non-thermal plasma technology – without any direct contact with your systems.

- Pneumatic transport

Bulk materials such as cut tobacco, tea, chips or crystal sugar are transported gently with our pneumatic transport system to keep production changes to an absolute minimum. Our patented SACU tobtronic® is the most effective and safest technology to ensure blockage-free, pneumatic conveying of bulk materials at a low speed. The patented FPC pipe couplings avoid gaps and edges that can affect the bulk material.

- SACU tobtronic® – Smart tobacco transport control

Achieve gentle and efficient material handling with our smart SACU technology. Our patented SACU tobtronic® is one of the most effective technologies available for transporting cut tobacco gently during pneumatic conveying. It increases tobacco yield in cigarette making and reduces the downtime of cigarette makers. The system, made up of two units, continuously measures air and cut tobacco speed in the feeding pipe and regulates transport to as low a speed level as possible.

- Blend Selector & T-Switch

Our Blend Selector ensures maximum tobacco feeding flexibility between primary and secondary, plus automatic pipe connection monitoring. Given the different tobacco blends and the various cigarette and pack formats, a high degree of flexibility is required for the pneumatic bulk handling of cut tobacco from the primary to the cigarette makers with a tobacco feeder. Our Blend Selector with its connection control system provides reliable and safe conveying with seamless integration to the MES.

- PAC & MAC – Air flow control system

Air flow control systems for automated material and energy efficiency. The control of process air plays a major role in many industrial sectors due to the huge potential in terms of energy efficiency and process stabilisation. Our PAC (Process Airflow Control) unit is an air flow control system that can be easily adapted to any production type. The MAC (Maker Airflow Control) is an air flow control system that was developed specifically for the tobacco industry. Both systems minimise fluctuations and turbulence in extraction systems by reducing and homogenising the required air volume or negative pressure.

- WinU+ – Proven tobacco recovery systems

Yield improvement is one of the key issues for cigarette manufacturers. Every cut filler contains winnowers that can not be processed in the cigarette and are usually disposed of or returned to the primary (PMD). Our WinU+ technology is designed to separate, cut and re-feed of the blend specific winnower online to the cigarette maker - fully automatically. The winnower structure and particle size is adjustable according to the respective tobacco.

- TIRS & TRS plus – Proven tobacco recovery systems

TIRS & TRS plus provide tobacco recovery rates of up to two percent of total product volume. The TIRS and TRS plus tobacco recovery machines were developed to recover tobacco that would otherwise end up in the central filter system. This tobacco recovery technology enables the separation of any high-quality tobacco fibres from the tobacco dust of the cigarette machine and feeds them directly back into the production. Both systems are installed on the dedusting line and offer various advantages in terms of recovery rates, adjustability, machine footprint and flexibility, for example with a stand-alone system.

- VAC & NetVac® – Industrial central vacuum cleaning systems

Our industrial central vacuum cleaning systems improve the working conditions of your employees, increase plant availability and reduce wear and tear. Industrial central vacuum cleaning systems are more efficient than mobile industrial vacuum cleaners. These central vacuum cleaning systems ensure that any removed material, such as dust, bulk material or production residues, are collected in a central location. As a result, waste disposal is much simpler. There is no limit to the number of cleaning points that can be installed.

- Central dust and material handling – industrial dust collection system

A central industrial dust collector enhances the efficiency and cleanliness of machines, systems and buildings. Our dust collector systems consolidate bulk materials, dusts or products at central locations. When the dust collection system is in suction operation, the bulk material is automatically taken from the collection points and then transported over long distances. At the receiving point, the product is sent for further processing, loaded or compacted for disposal.

Download

GreenLine

GreenLine

- Publication in Tobacco Journal International

- New strategy for energy savings and increased tobacco yield

- Customer case story – Heintz van Landewyck

Download

Secondary Solutions

Download

COPLAS clean

COPLAS clean

- Expert article on odour reduction

- Publication in TOBACCO International

- Interview with Lars Kükenshöner

References