You can contact us via phone and email or use our contact form. We are looking forward to hearing from you!

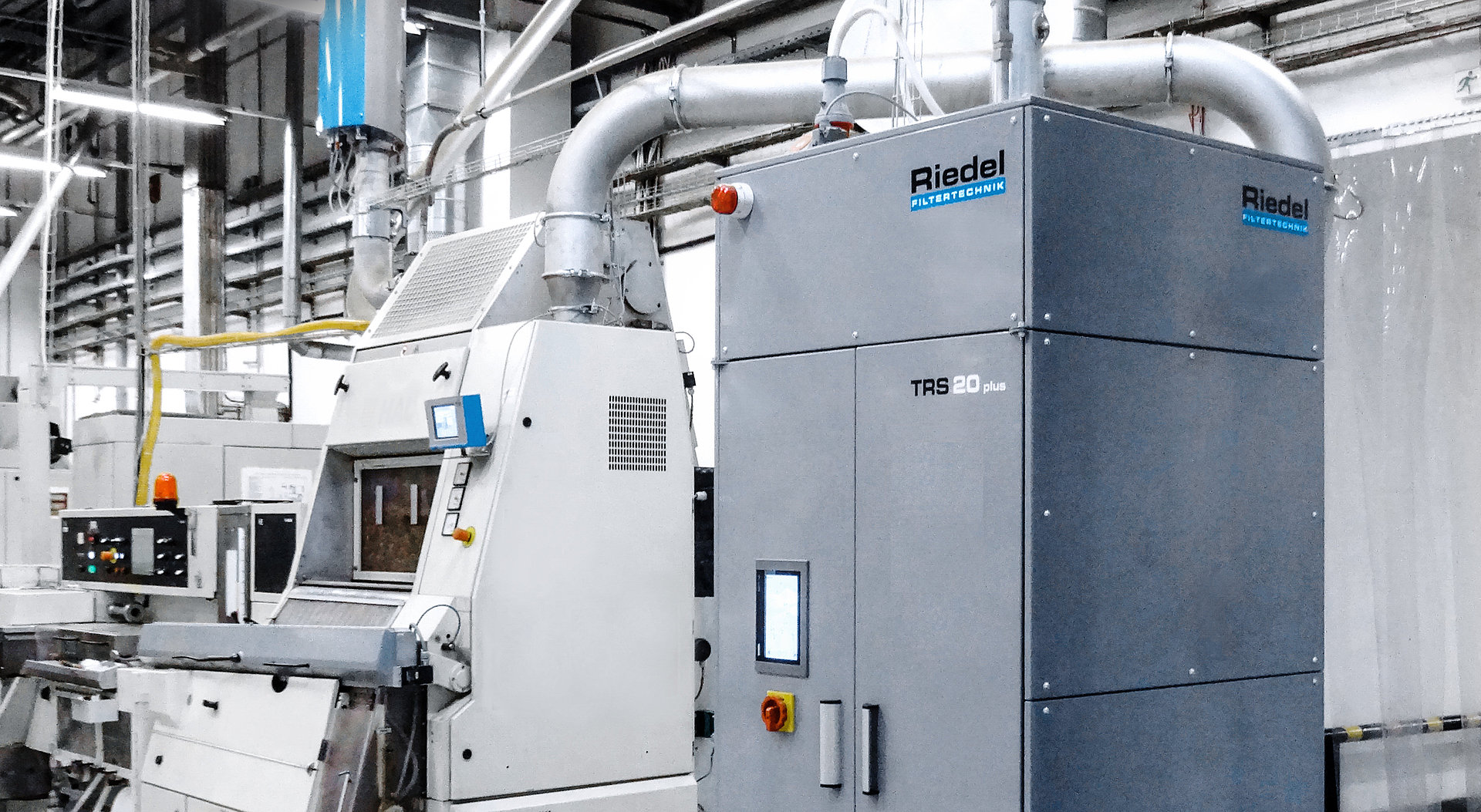

Shorts recovery TIRS & TRS plus

Product recovery

The TIRS and TRS plus tobacco recovery machines were developed to recover tobacco that would otherwise end up in the central filter system. This tobacco recovery technology enables the separation of any high-quality tobacco fibres from the tobacco dust of the cigarette machine and feeds them directly back into the production. Both systems are installed on the dedusting line and offer various advantages in terms of recovery rates, adjustability, machine footprint and flexibility, for example with a stand-alone system.

Advantages – TIRS

- No space required

- Installed directly onto the cigarette maker dedusting line

- Lower energy consumption

- Reasonable maintenance requirements

- Tobacco recovery rate of 0.5%-1.0%

- Targeted particle size for customer-specific requirements and production parameters

- Rapid ROI

Advantages – TRS plus

- Tobacco short recovery rate of up to 2% of the total tobacco amount

- Tobacco short recovery efficiency of more than 98%

- Recovery of desired particle sizes

- No blend-specific settings required

- Flexible positioning on the cigarette maker

- Easy installation on the cigarette maker

- Continuous return of tobacco shorts to the cigarette maker hopper

- Zero impact on the capacity and performance of existing feeding and maker dedusting systems

Markets

- Tobacco

We have been an innovative partner to the tobacco industry for over 50 years. We are established worldwide as a system supplier of exhaust air purification and industrial odour reduction systems in the manufacturing of cigarettes. Our pneumatic transport systems, central vacuum cleaning systems and machine cleaning systems are designed to achieve our main goals: environmental protection, energy efficiency and increased yield in the tobacco industry. We continue to innovate in the primary and secondary sectors with effective and patented technologies.

- Tea

References