Learn more about our service here.

COPLAS clean

Cold plasma technology for odour control

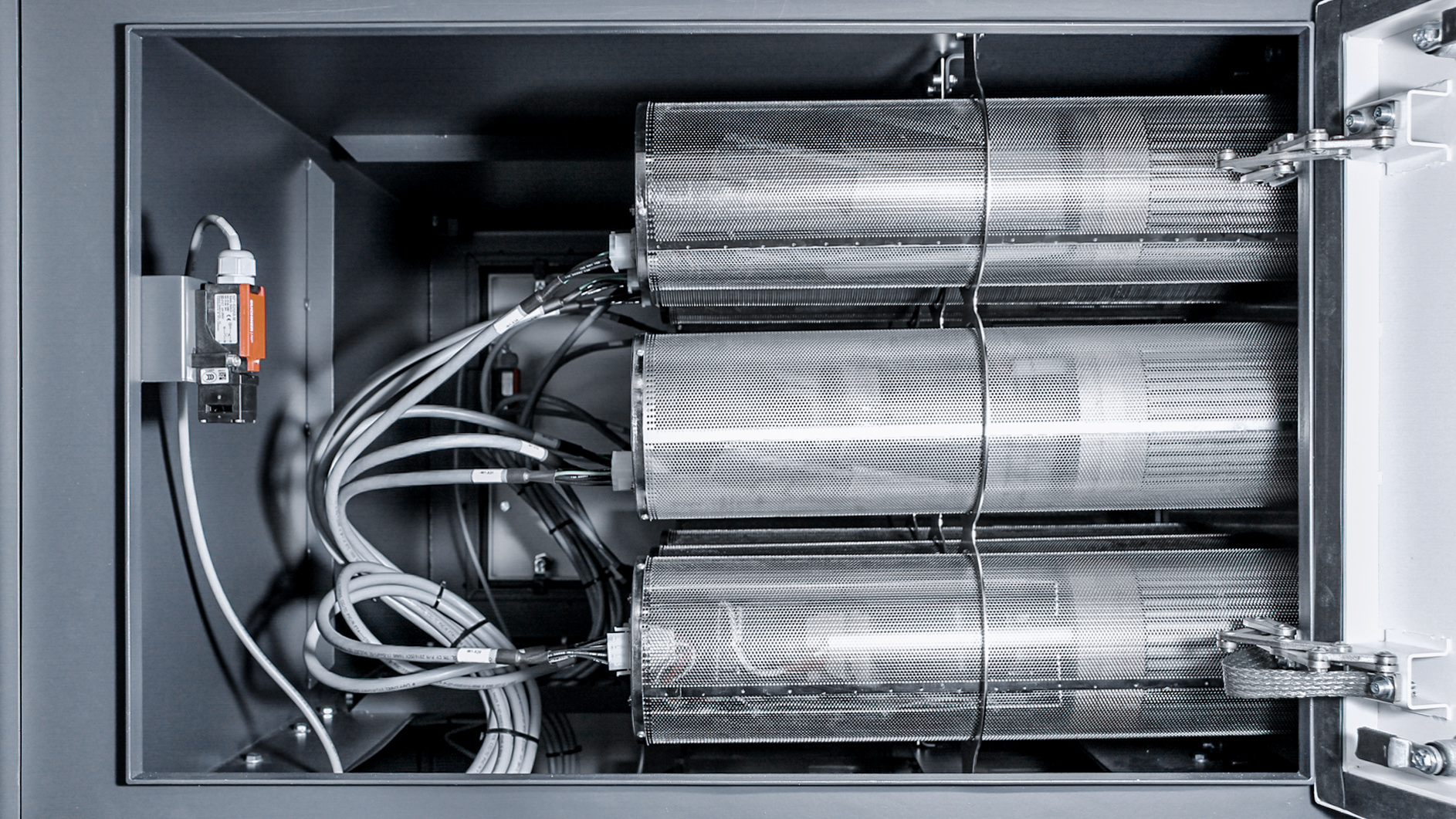

COPLAS clean is our cold plasma technology for air cleaning. Odours are eradicated without any chemicals, water or waste. Our patented plasma reactors produce reactive oxygen and OH radicals, which are then injected into the exhaust air. The ingenious result is that odour molecules are oxidised in just milliseconds by non-thermal plasma technology – without any direct contact with your systems.

Advantages

- Maximum odour reduction – rapid oxidation through radical reactivity

- Sustainability – odour elimination without water, chemicals or waste

- Low maintenance – no system contamination thanks to the injection principle

- Modular design – flexible and easy to install

- Energy efficiency – low operating costs and flexible plasma performance to suit even fluctuating process conditions

Features

- Stand-alone system with integrated control cabinet

- Space-saving

- No pressure drop in the exhaust duct

- Backflow protection through automatic back stream flaps

- Start-stop system – no start-up time

- Plasma power adjustment with 1% incremental control

- Patented plasma reactors with Venturi effect for maximum radical yield

Markets

- Tire / Rubber

Riedel Filtertechnik offers a wide range of standard and individual solutions for process exhaust in tire production – from dust extraction to odour emission reduction. Our specially designed dust extraction systems keep emissions well below the limit values of 10 mg/m³. That typical smell of rubber is eliminated by our COPLAS clean cold plasma air cleaner system in an energy-efficient and reliable way. So, tire production can become more sustainable than with conventional technologies.

- Tobacco

We have been an innovative partner to the tobacco industry for over 50 years. We are established worldwide as a system supplier of exhaust air purification and industrial odour reduction systems in the manufacturing of cigarettes. Our pneumatic transport systems, central vacuum cleaning systems and machine cleaning systems are designed to achieve our main goals: environmental protection, energy efficiency and increased yield in the tobacco industry. We continue to innovate in the primary and secondary sectors with effective and patented technologies.

- Food

Cereals, oil or milk powder – food production is characterised by the variety of food products alone. Countless process steps including extrusion, drying, cooling or product packaging are completed for their production. As a result, dust or strong-smelling odour emissions are inevitably released into the environment and are subject to strict limits. We help our customers to comply with these emission limits by offering a wide range of products – from dust removal to industrial odour control systems.

- Pet food

Pet food production involves numerous process steps – extrusion, drying, cooling, machine extraction or even wet food cooking. During the processing of wet and dry pet food, dusts and odorous substances are released into the exhaust air, which can pollute the environment. Riedel Filtertechnik offers a wide product portfolio with individual solutions for pet food production. We cover everything from dust extraction and dedusting of conveyors, extruders and dryers to the reduction of odour emissions.

- Compound feed

In compound feed production, odour-intensive substances are often added for specific recipes. As a consequence, odour emissions are produced that can pollute the environment. Grinding fine, dry ingredients and pelleting also produces dust emissions, which can be controlled using our filter systems. Our COPLAS clean cold plasma technology for air cleaning reduces any odours sustainably without any chemicals or waste products.

- Fish food / Fish meal

- Glass recycling

- Rendering Animal Products

Download

Case Studies

Case Studies

- COPLAS clean Case Studies

- Pet food manufacturer in Austria

- Tire manufacturer in Germany

- Fish meal manufacturer in Germany

- Treatment of exhaust air from production processes

- Odour reduction via cold plasma technology

Download

White Paper

White Paper

- White Paper on odour emissions in the pet food industry

- Odour sources in the production process

- Comparison of various technologies

- Process specific customization of cold plasma technology