You can contact us via phone and email or use our contact form. We are looking forward to hearing from you!

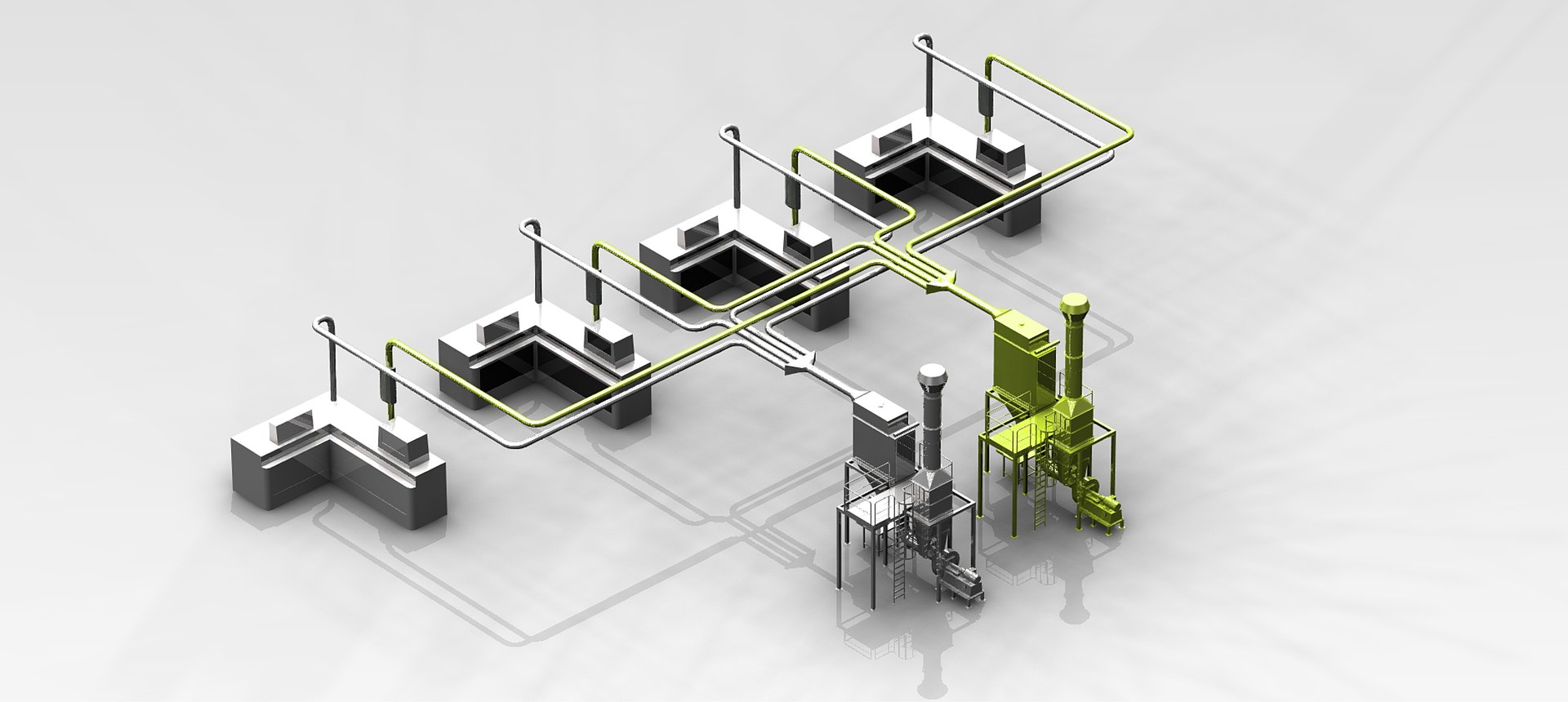

Air flow control system – PAC & MAC

Process air control

The control of process air plays a major role in many areas of industry, due to the high potential for energy efficiency and process stabilization. Our PAC control unit (Process Airflow Control) can be adapted flexibly to any production type. The MAC (Maker Airflow Control) was developed specially for the tobacco industry, however. Both systems minimize fluctuations and turbulence in the extraction systems by reducing and homogenizing the necessary air volume or negative pressure. Settings can be adjusted automatically via hand flaps, to ensure optimal flap position. Our control units are available for volume flows from 180 to 7,000 m³/h.

ADVANTAGES – PAC

- Consistent process conditions

- Increased yield through lower reject rates

- Feasibility of various production states

- Current process status display

- Two possible operating modes to regulate negative pressure in the pipeline

- Airflow control through step-controlled flap

- Reduction in energy consumption by up to 40% when combined with integrated VSD on the dedusting fan

- Simple operation and maintenance

ADVANTAGES – MAC

- Rod homogeneity

- Increased material efficiency and tobacco yield

- Reduction in waste, degradation, fine particles and dust

- Lower reject rates from the manufacturing machine

- Better cigarette firmness

- Integrated control with user-friendly touch panel for visualisation and parameterisation with optional connection to existing SACU tobtronic® touch panel

Markets

- Tire / Rubber

Riedel Filtertechnik offers a wide range of standard and individual solutions for process exhaust in tire production – from dust extraction to odour emission reduction. Our specially designed dust extraction systems keep emissions well below the limit values of 10 mg/m³. That typical smell of rubber is eliminated by our COPLAS clean cold plasma air cleaner system in an energy-efficient and reliable way. So, tire production can become more sustainable than with conventional technologies.

- Tobacco

We have been an innovative partner to the tobacco industry for over 50 years. We are established worldwide as a system supplier of exhaust air purification and industrial odour reduction systems in the manufacturing of cigarettes. Our pneumatic transport systems, central vacuum cleaning systems and machine cleaning systems are designed to achieve our main goals: environmental protection, energy efficiency and increased yield in the tobacco industry. We continue to innovate in the primary and secondary sectors with effective and patented technologies.

- Sugar

We have been an established partner to the global sugar industry for dedusting and sugar conditioning for decades. Our in-depth process knowledge makes us more than just an equipment supplier for many of our customers. As a process solution partner, we develop individual concepts together with our customers – perfectly matched to the specific requirements and circumstances.

- Food

Cereals, oil or milk powder – food production is characterised by the variety of food products alone. Countless process steps including extrusion, drying, cooling or product packaging are completed for their production. As a result, dust or strong-smelling odour emissions are inevitably released into the environment and are subject to strict limits. We help our customers to comply with these emission limits by offering a wide range of products – from dust removal to industrial odour control systems.

- Pet food

Pet food production involves numerous process steps – extrusion, drying, cooling, machine extraction or even wet food cooking. During the processing of wet and dry pet food, dusts and odorous substances are released into the exhaust air, which can pollute the environment. Riedel Filtertechnik offers a wide product portfolio with individual solutions for pet food production. We cover everything from dust extraction and dedusting of conveyors, extruders and dryers to the reduction of odour emissions.

- Compound feed

In compound feed production, odour-intensive substances are often added for specific recipes. As a consequence, odour emissions are produced that can pollute the environment. Grinding fine, dry ingredients and pelleting also produces dust emissions, which can be controlled using our filter systems. Our COPLAS clean cold plasma technology for air cleaning reduces any odours sustainably without any chemicals or waste products.

References