You can contact us via phone and email or use our contact form. We are looking forward to hearing from you!

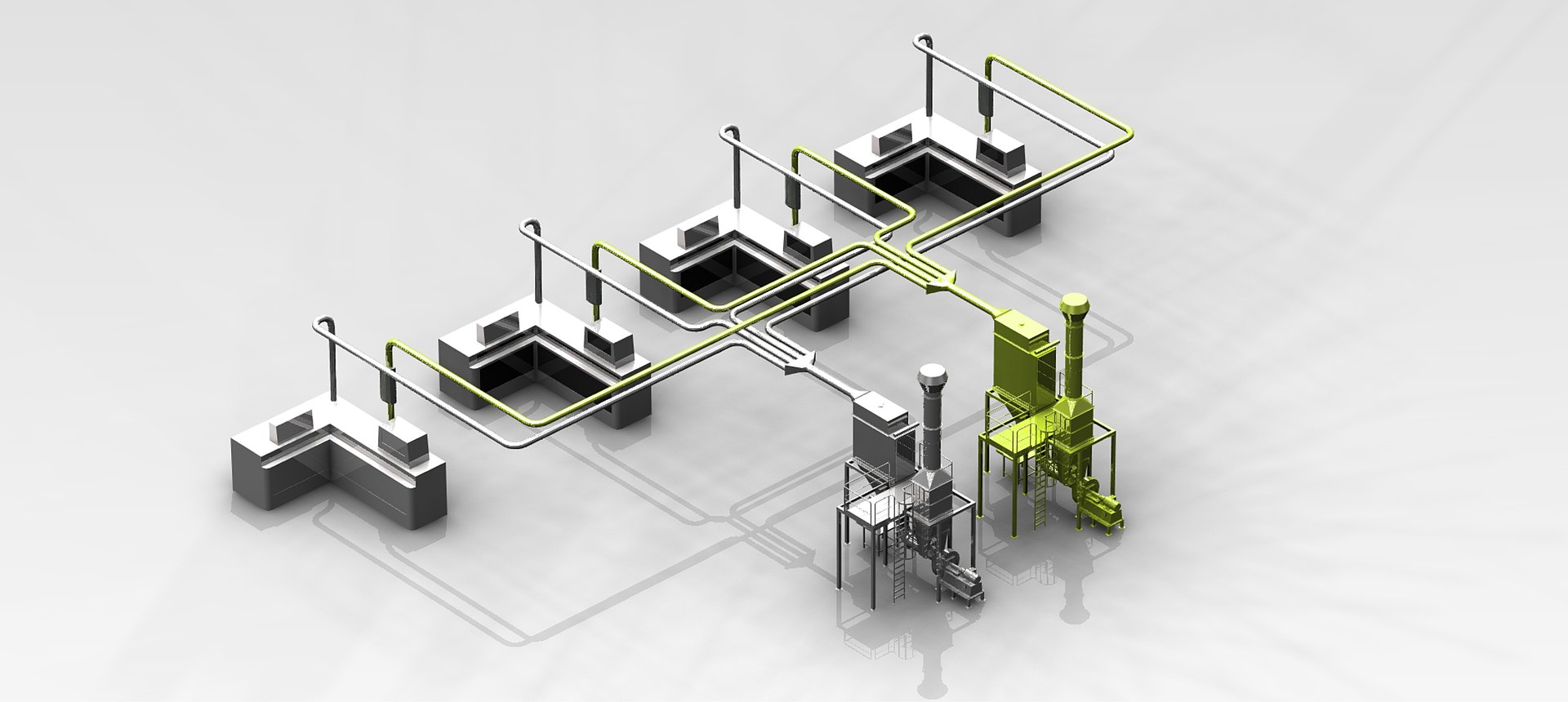

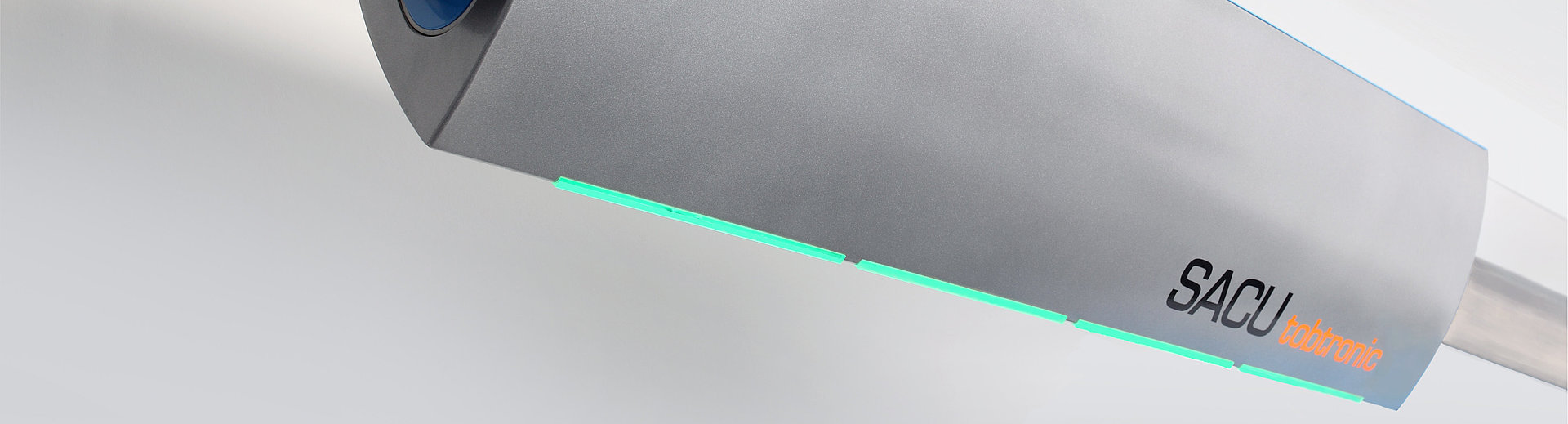

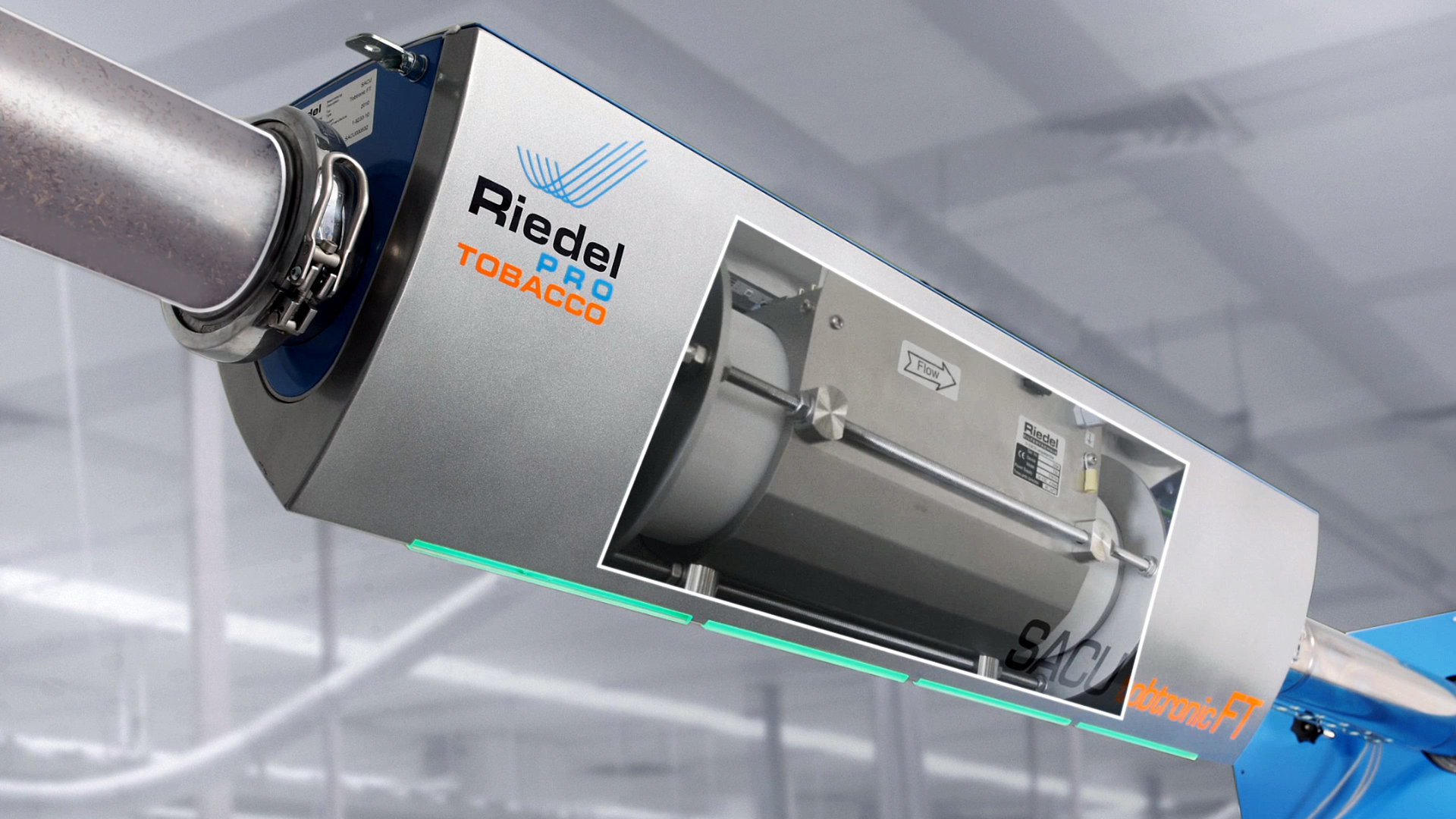

SACU tobtronic® for pneumatic transport of tobacco

Transport control

Our patented SACU tobtronic® is one of the most effective technologies available for transporting cut tobacco gently during pneumatic conveying. It increases tobacco yield in cigarette making and reduces the downtime of cigarette makers. The system, made up of two units, continuously measures air and cut tobacco speed in the feeding pipe and regulates transport to as low a speed level as possible. The integrated anti-blockage control function prevents blockages inside the piping.

Advantages

- Higher material efficiency and improved tobacco yield

- Improved cut tobacco quality

- Reliable and on-demand supply of cut tobacco

- Reduced energy costs

- Compatibility with all feeder and maker types

Features

- Measuring and regulation of air and cut tobacco conveying speed

- Leakage monitoring and compensation for the receiving airlock of the cigarette maker

- Maintenance functions such as differential pressure and leakage display on the receiving airlock

- Priority feeding mode to ensure supply of cut tobacco

- Integral part of Eco Mode for energy savings

Markets

- Tobacco

We have been an innovative partner to the tobacco industry for over 50 years. We are established worldwide as a system supplier of exhaust air purification and industrial odour reduction systems in the manufacturing of cigarettes. Our pneumatic transport systems, central vacuum cleaning systems and machine cleaning systems are designed to achieve our main goals: environmental protection, energy efficiency and increased yield in the tobacco industry. We continue to innovate in the primary and secondary sectors with effective and patented technologies.

- Coffee

- Tea

References