You can contact us via phone and email or use our contact form. We are looking forward to hearing from you!

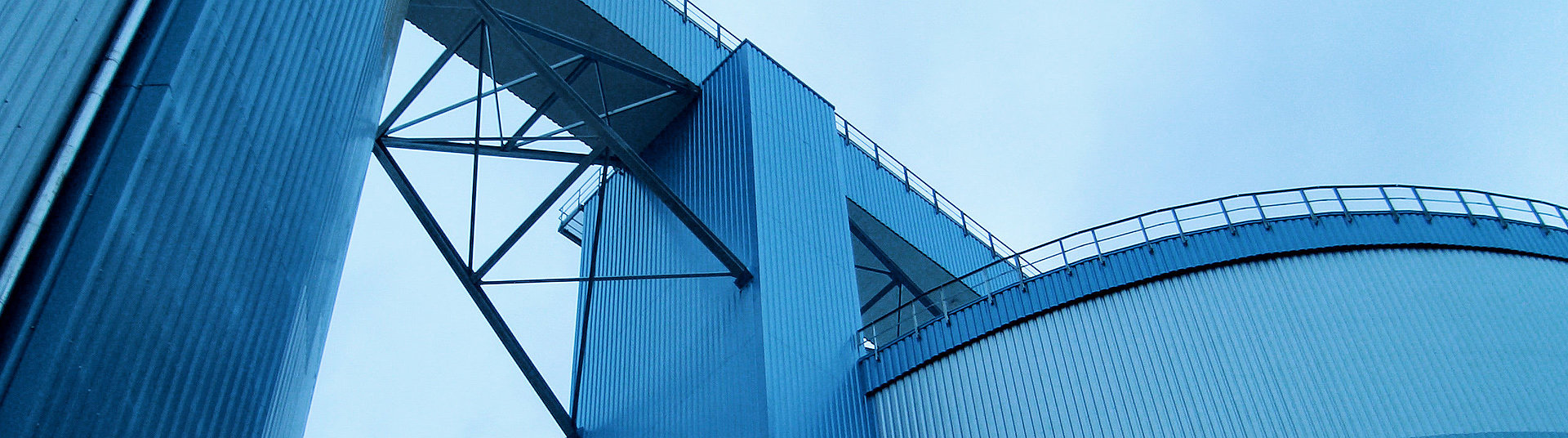

Silo conditioning

Products

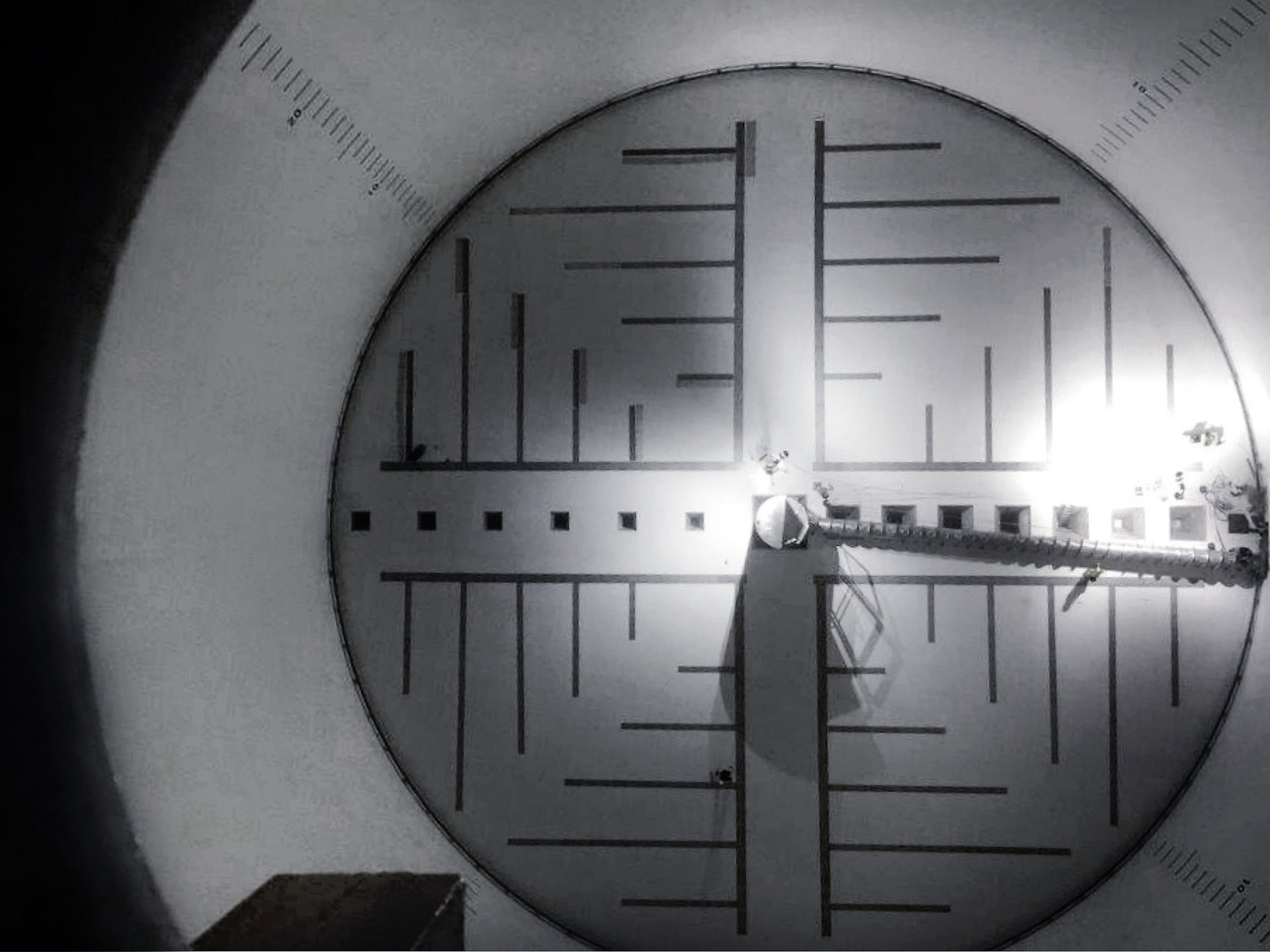

Even when sugar is dried and cooled, there is residual moisture left behind in the crystals. The result? Lumps can form. We can minimize this risk using our silo conditioning technology: Using a regulated quality of air, we condition the sugar to defined process parameters. The conditioned air is extracted, dedusted and then returned to the process. Enrichment with fresh air only takes place if it is more energy efficient than comprehensive air treatment.

Advantages for you

- Process reliability thanks to consistent product quality

- Reliable transportability of sugar

- Energy-efficient operation thanks to intelligent air management

- Facilitation of 100% silo discharge

- Reduced risk of infection

- Increased occupational safety through minimizing manual work in the silo

Features

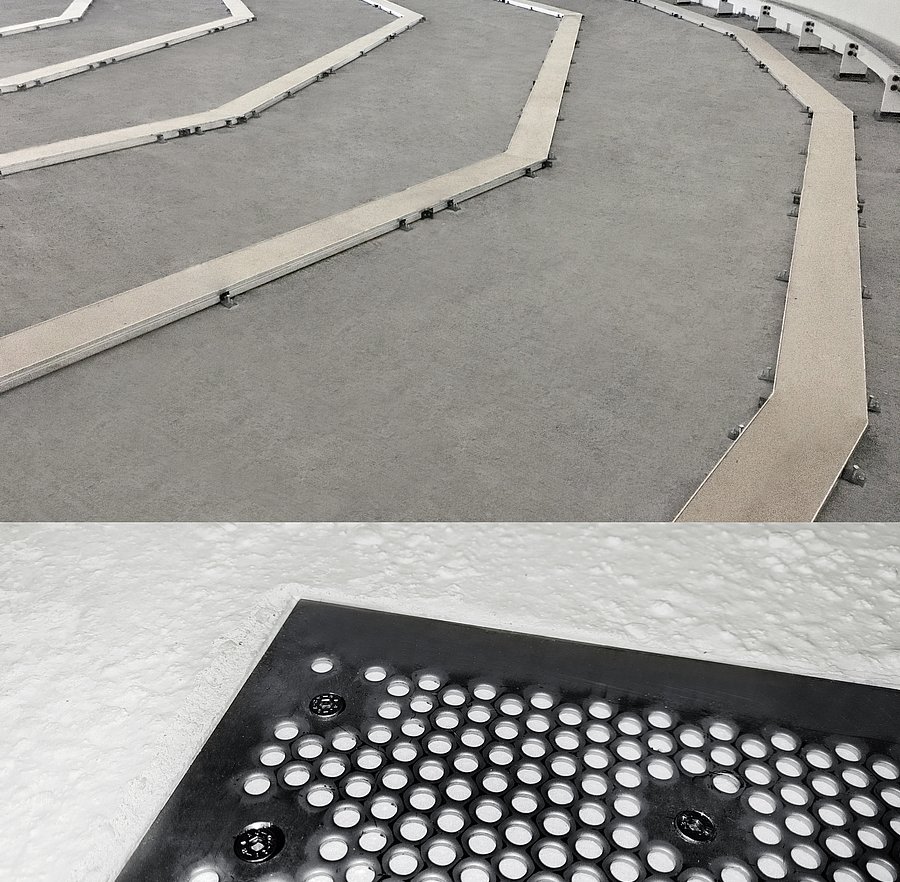

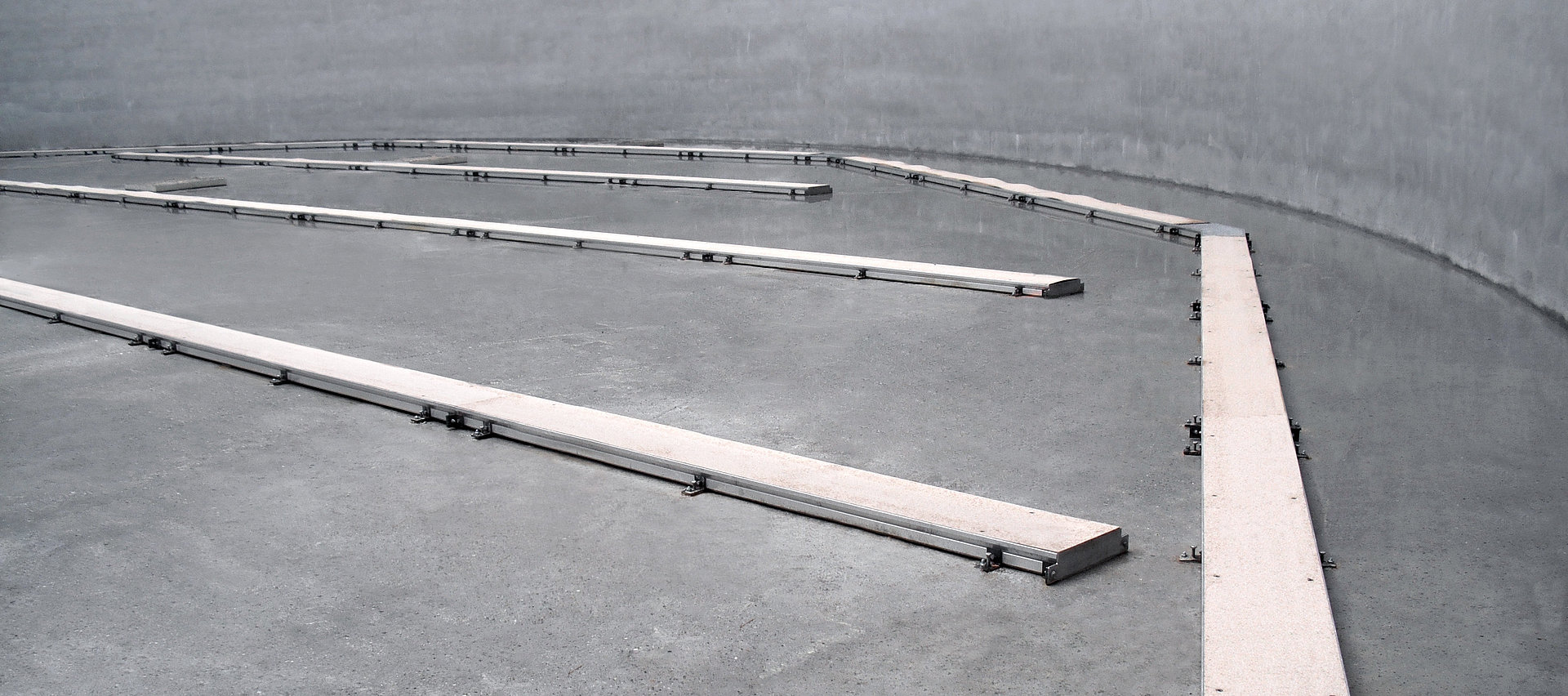

- Specially developed tailored channels for even air distribution

- Hygienic and no-maintenance design of the air distribution ducts

- Controlled air treatment process

- Central dedusting system – even for multiple silos

- Reuse of cleaned air

Markets

- Sugar

For decades, we have been an established partner of the global sugar industry for dedusting as well as for sugar conditioning. Thanks to our profound process knowledge, we are more than just an equipment supplier for many of our customers. As a process solution partner, we develop individual concepts together with our customers - perfectly matched to the respective requirements and circumstances.

References